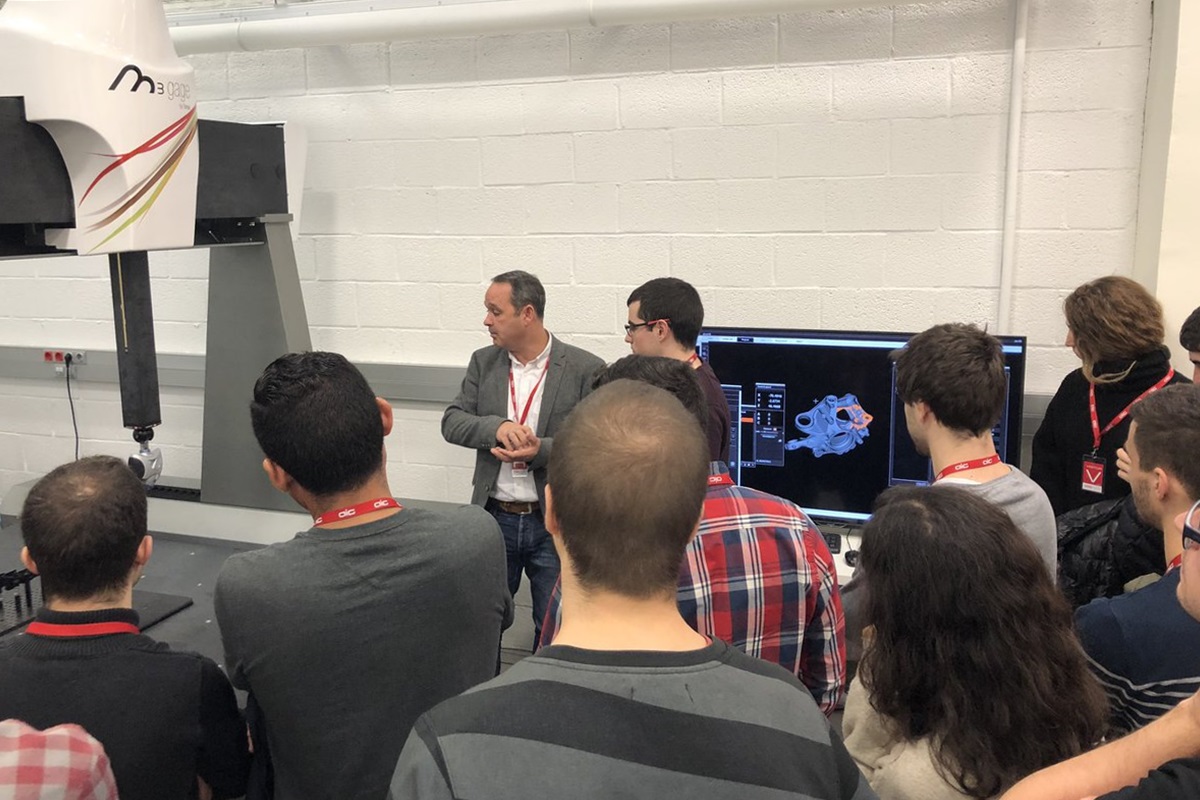

Innovalia Metrology continues to deepen its commitment to training in metrology and quality management. in this regard, it has opened the door of its laboratory in the AIC-Automotive Intelligence Center in Boroa, where future talents could witness one of the most innovative solutions in metrology that is helping the positioning of the Basque company as a driver for Smart Metrology in Europe

Both engineering students of the University of the Basque Country currently specializing in Metrology, as well as students of the the One Talent program of Corporate University of Gestamp, have enjoyed for the first time a hybrid measurement of a chassis combining the optical sensor (Optiscan) with a palpation sensor, besides discovering the importance of M3, a universal platform which allows to control the quality of the parts measured in Machine Tool, with a measuring arm or in CMM with the help of the fixing tools.

Innovalia Metrology collaborates in the training of new professionals by showing them how the impact of technology has revolutionized both consumption and production models and that is why its use not only improves products and manufacturing times but also introduces alternatives that they transform the sector. In this sense, the solutions proposed by Innovalia Metrology meet the challenge and enable the development and delivery of the products, causing the value to be transferred from the product to the service, since digital advances allow to improve the processes and increase their speed, being able to implement flexible functions and adapt products to what consumers demand.

Upcoming stops before the end of the year

2025 is coming to an end, but we still have a couple of key destinations to visit on our international calendar. At Innovalia Metrology, we will close the year by strengthening our presence at two strategic events that will allow us to continue bringing our advanced...