This past Thursday, December 13th, Innovalia Metrology opened the doors of its Metrology Lab to students of the UPV currently doing an Engineering Masters.

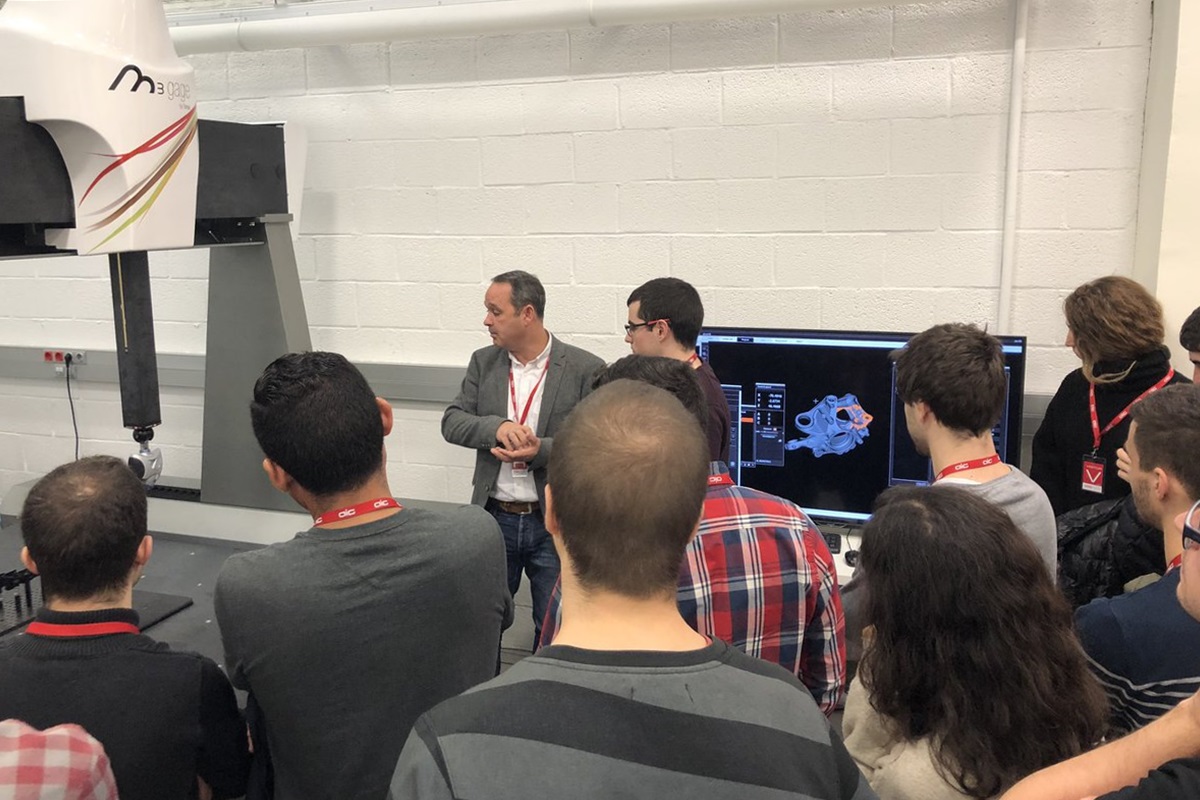

Guided by Naiara Ortega, one of the Masters teachers in Metrology at the UPV, and by the team of the Innovalia Metrology unit at the AIC of Boroa, the students witnessed a display of metrological technology applied to real automotive cases.

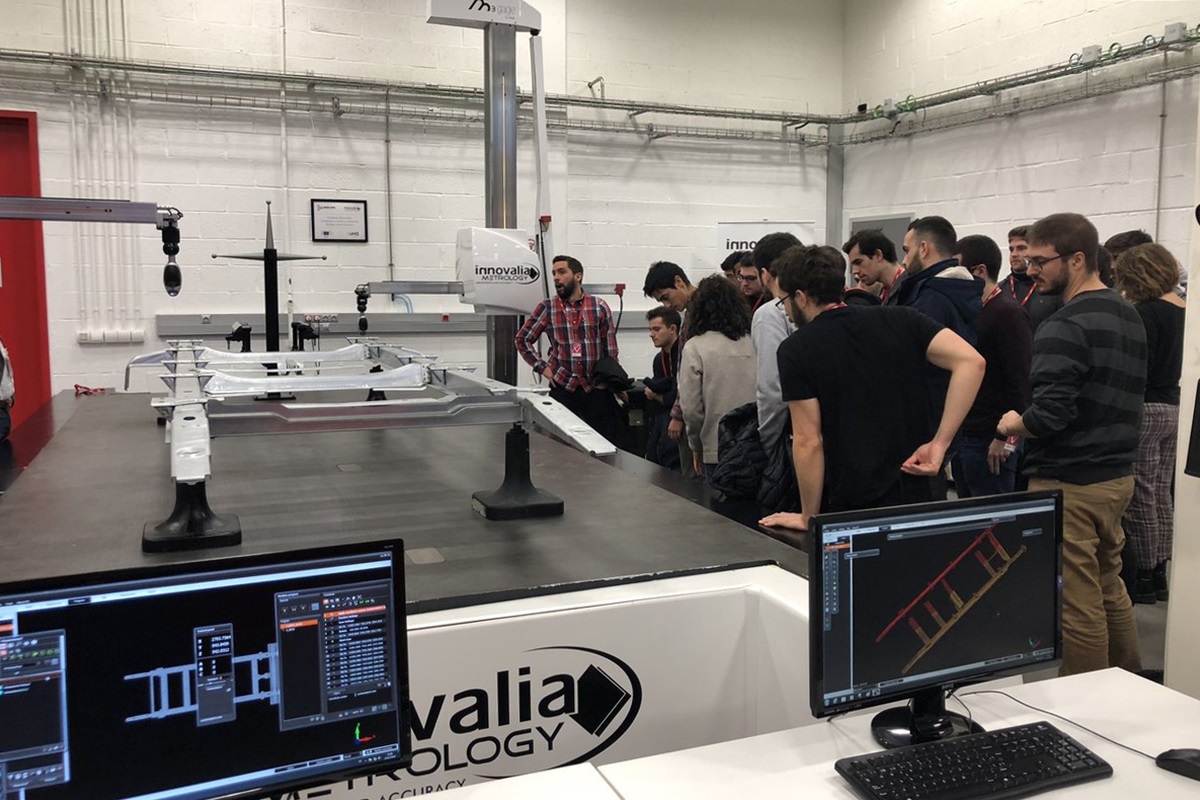

Innovalia Metrology has different Metrology solutions in its laboratory that allow you to visualize the different measurement processes in the real production systems.

Thanks to M3 Hybrid, the students could see for the first time a hybrid measurement of a chassis, measurement made with an Optical sensor (Optiscan) combined with a touch probe, in a duplex MMC. In addition, the Basque company made available to students another of their machines, a bridge machine (Spark) where he made a complete hybrid measurement, thanks to M3 Hybrid, of a piece of machining.

Thanks to this visit, the UPV students could visualize, thanks to M3 the importance of having a universal platform from which you can control the quality of the parts measured in Machine Tool, with an arm or with a CMM!

Innovalia Metrology is still committed to Digital Metrology and therefore introduced its Optiscan optical sensors. Optical sensors to obtain high accuracy 3D point clouds of your products for reverse engineering, virtual metrology and automatic inspection.

The Industrial sector is evolving towards a digital and interconnected production, that is why Innovalia Metrology is committed to train young talents in technology that allows them to talk about digital parts, intelligent metrology and measurement systems that inspect the parts and allow us to optimize production in a proactive way.