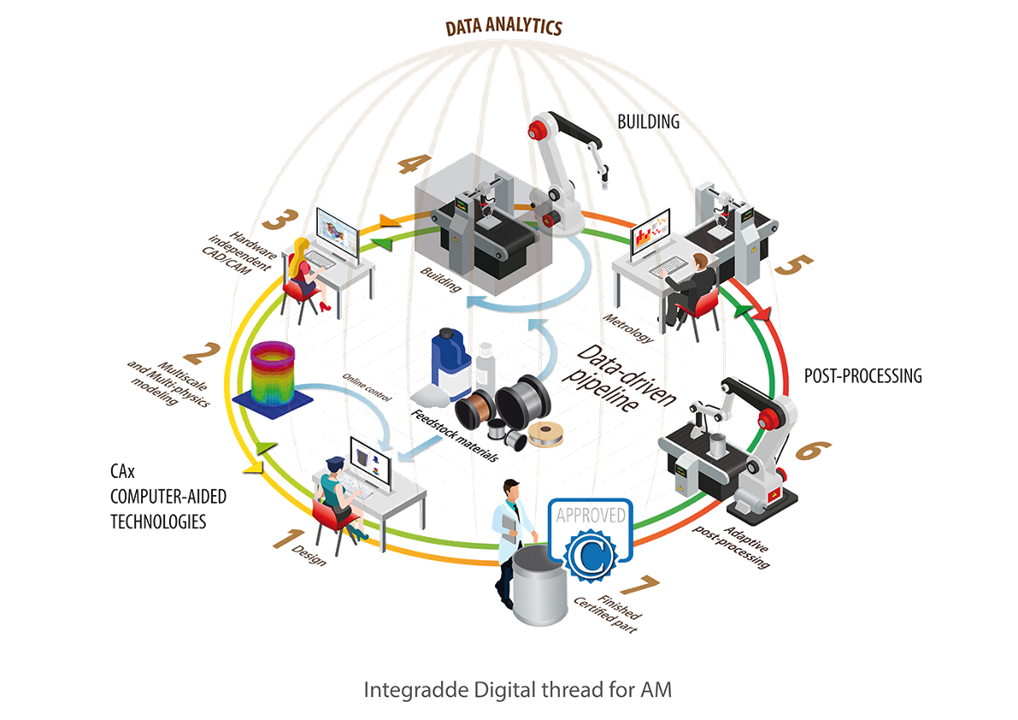

The Integradde project was born to develop a novel end-to-end solution capable of demonstrating the potential of Directed Energy Deposition (DED) processes for the manufacturing of certified large metal components in strategic metalworking sectors.

Integradde aims to develop a new manufacturing methodology capable of ensuring the manufacturability, reliability and quality of a target metal component from the initial product design. It combines research on building strategy optimization, multi-scale and multi-physics modelling, hardware-independent building process, automatic building strategy generation, online self-adaptative control and inline quality assurance for the manufacturing of certified metal parts, addressing mass customization manufacturing approach.

The main goals or steps that the Integradde project will take to achieve that are to develop novel multistage pilot plants based on DED processes, hybridizing AM with previous and subsequent processes for the manufacturing of several certified metal parts. Develop novel data-driven pipeline supporting the design, simulation and production planning for additive manufacturing. Implement a Quality-by-Design (QbD) manufacturing strategy, based on real-time control systems, inline quality control systems and minimized consumption of raw materials. The Integradde project also wants to Implement a digital end-to-end engineering concept and demonstrate INTEGRADDE approach in several pilot lines for the manufacturing of certified metal parts.

The main goals or steps that the Integradde project will take to achieve that are to develop novel multistage pilot plants based on DED processes, hybridizing AM with previous and subsequent processes for the manufacturing of several certified metal parts. Develop novel data-driven pipeline supporting the design, simulation and production planning for additive manufacturing. Implement a Quality-by-Design (QbD) manufacturing strategy, based on real-time control systems, inline quality control systems and minimized consumption of raw materials. The Integradde project also wants to Implement a digital end-to-end engineering concept and demonstrate INTEGRADDE approach in several pilot lines for the manufacturing of certified metal parts.

Integradde has gathered over 25 european companies and institutions that are willing to work together to reach the integradde goals such as Atos, Datapixel, NIT, The Coimbra University, the University of Sheffield, Aimen, Acerlor Mittal, Bureau Veritas, Corda, DIN and much more.

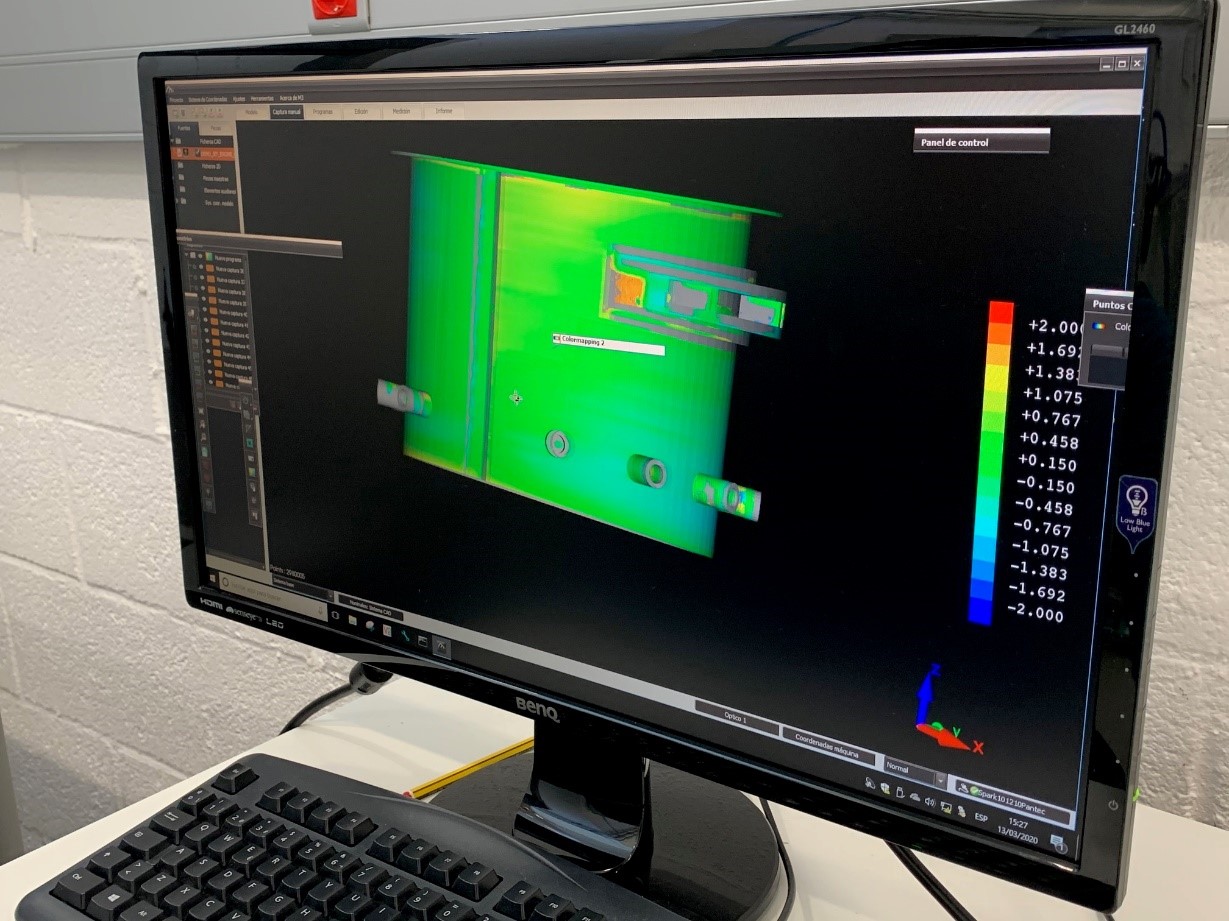

Datapixel, which is part of Innovalia Metrology, performs the design, development and commissioning of non-contact optical instrumentation in the production line and measurement laboratory for quality control, dimensional and geometrical inspection. Datapixel will supply Integradde with data collection and analysis systems, endorsed with cognitive abilities gaining knowledge from overall process, will assist in the quality verification but also design and manufacturing of new components, addressing mass customization manufacturing approach which will allow us to talk and deal with 3D dimensional inspection solutions, virtual metrology, in line inspection and robot guidance systems. The Quality assurance duty will allow the project not only to have the best outcome of the part but also to correct and give information on how the part is being made and being able to adjust the production. Innovalia Metrology, thanks to Datapixel has provided the Integradde proyect with M3 Hybrid, a high-tech Metrology solution formed by a bridge type machine, optical sensor and measuring software that will scan and digitize the parts, providing digital copies of each part and making it easy to measure, examine and share at any time.

Optiscan, 3D Optical sensor from Datapixel scanning the metal part

M3 Software, measuring and analysis software from Datapixel, managing the data and sharing the results of the metal part through a color mapping.