AUKOM

The AUKOM course conveys and reinforces the fundamental knowledge of manufacturing metrology for beginners and advanced measurement technicians with state-of-the-art teaching methods.

1.1 BASIC FUNDAMENTALS DIMENSIONAL METROLOGY

This course conveys and reinforces the fundamental knowledge of manufacturing metrology for beginners and advanced measurement technicians with state-of-the-art teaching methods.

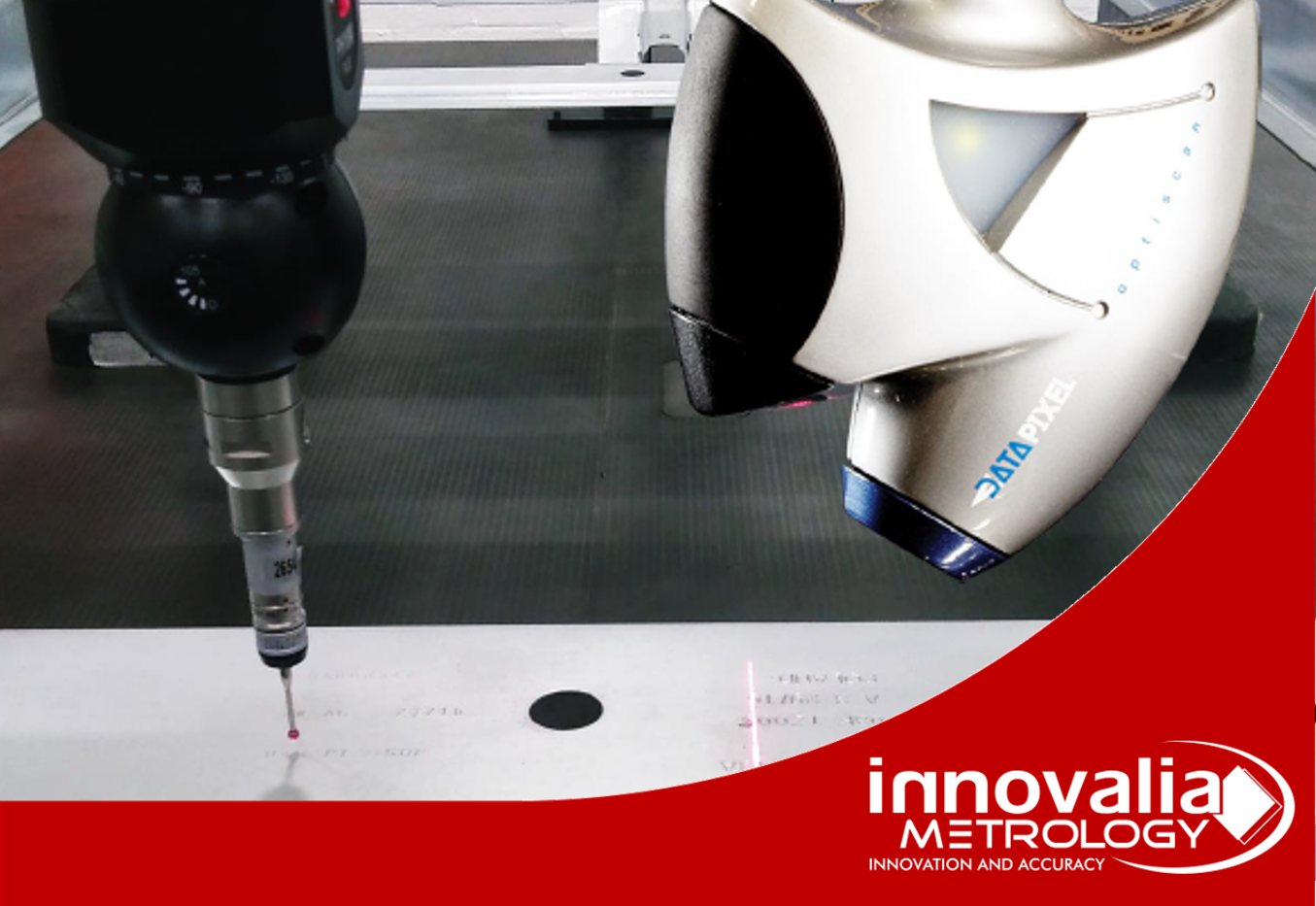

2.1 CONTACT MEASUREMENT

The course covers the main advantages and disadvantages of contact measurement, as well as the strategy to be taken into account in stylus measurement.

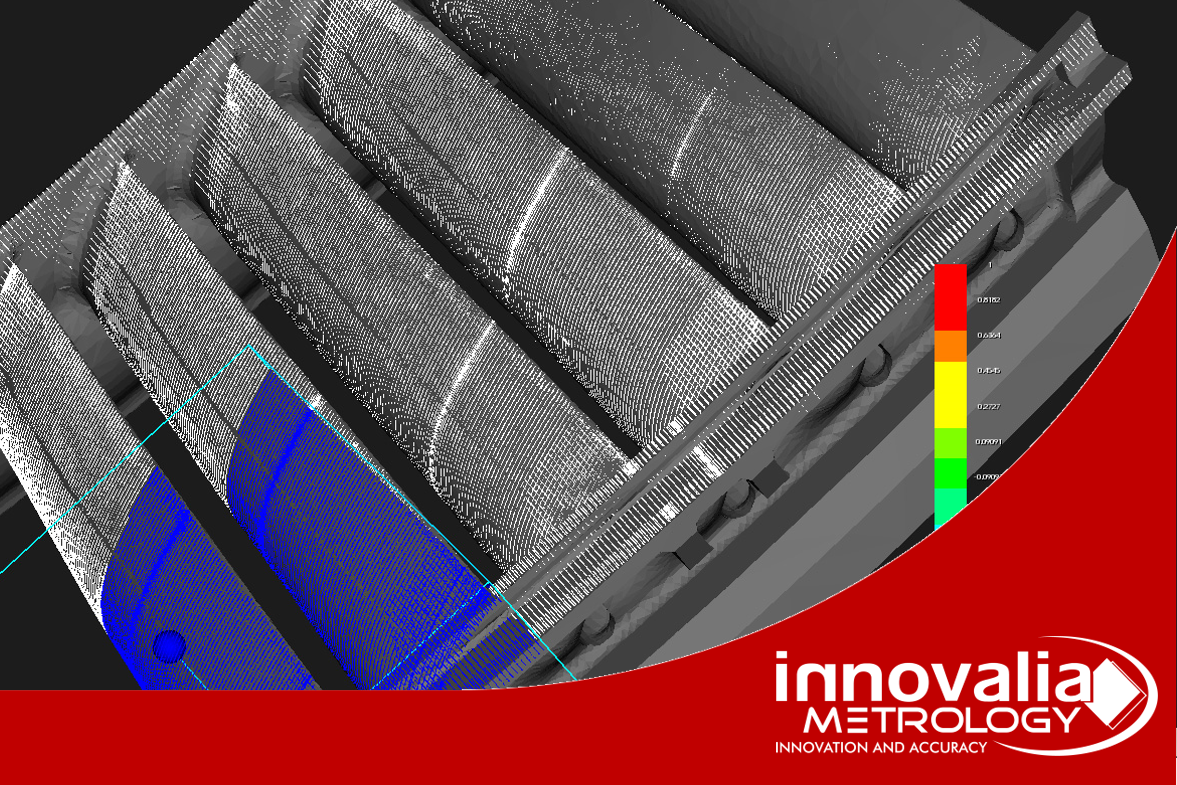

2.2 VIRTUAL METROLOGY TECHNIQUES BY 3D OPTICAL DIGITIZING

The course covers the principles of non-contact measurement, including a description of the different techniques, an introduction to geometric elements and formats, combining a theoretical overview with practical examples.

2.3 HYBRID MEASUREMENT

The course deals with the main advantages and disadvantages of contact and non-contact measurement, as well as the combination of both, through the deployment of a series of theoretical and practical examples and the use of quality data acquisition and processing tools.

CMM CALIBRATION

This course covers the points to be taken into account in the calibration process of a coordinate measuring machine to ensure the accuracy and reliability of the measurements made with it.

CONTROL MOCK-UPS AND FIXTURING SYSTEMS FOR CMM

The course analyzes the different aspects to consider when designing and/or acquiring and validating a control model.

IN PROCESS MEASUREMENT SOLUTIONS: MEASUREMENT ON MACHINE TOOLS

The course addresses the problems of positioning and measurement within the machine tool.